+86-0523-83274900

+86-151 9064 3365

Adjustable nozzle-machino are highly flexible liquid spray equipment with functions such as adjustable spray angle, flow rate and multiple spray modes. The equipment is widely used in many fields such as industry, agriculture, environmental protection, fire protection, food processing, chemical industry, etc. with its precise, efficient and intelligent operation mode, and is an important part of modern liquid spray control system.

1. Structural composition

Adjustable nozzle

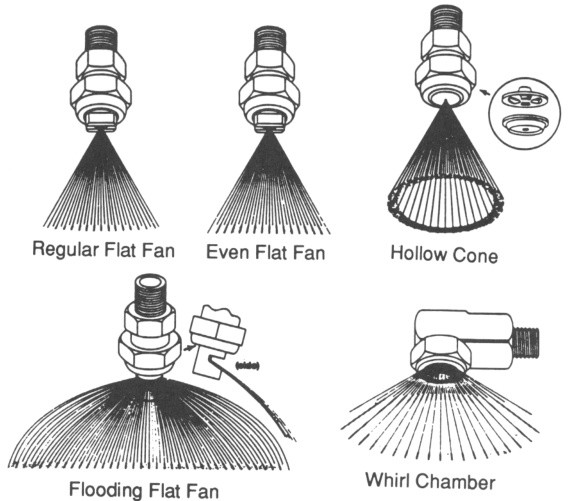

The adjustable nozzle is the core component of the adjustable nozzle, which directly determines the accuracy and flexibility of the spray effect. It is usually designed with an adjustable spray angle function ranging from 0° to 120°, which is convenient for users to adjust the coverage and direction of the spray according to actual needs. At the same time, the nozzle supports a variety of spray forms, such as linear spray, fine atomization spray, wide fan spray, etc., which can adapt to different spray tasks. The spray particle size and flow rate can also be adjusted according to the use scenario to achieve precise control of the liquid spraying amount and particle size, ensuring uniform and efficient spraying.

Liquid supply system

The liquid supply system is an important component to ensure the normal operation of the nozzle, mainly composed of a liquid storage tank, a water pump or a booster system. The liquid storage tank is used to store the liquid to be sprayed, and its capacity can be customized according to needs. The water pump or booster system is responsible for pressurizing the liquid and delivering it to the nozzle stably to ensure stable pressure and uniform spray effect when the nozzle sprays. The system design focuses on the stability of flow and pressure to avoid poor spray effect due to uneven liquid supply or pressure fluctuations.

Control system

The control system provides intelligent support for the operation of the nozzle, which can be manually adjusted or automatically controlled. Users can accurately set the spray parameters, including spray angle, flow rate, spray time, etc., through an electronic panel, PLC controller or remote control device. Advanced control systems also support programmed timed spraying, remote monitoring and data feedback, which greatly improves the automation and intelligence level of the equipment, makes operation more convenient and efficient, and reduces human errors.

Bracket or mobile platform

In order to adapt to different use environments and operating requirements, the adjustable nozzle machine is equipped with a variety of bracket or mobile platforms. Depending on the usage scenario, the equipment can be fixedly installed to ensure that the spraying equipment works stably in a specific location; it can also be designed to be portable for easy on-site movement and rapid deployment; or it can be equipped with an automatic mobile platform to achieve autonomous movement of the spray head machine to cover a wider area. This diverse installation method greatly improves the flexibility and applicability of the equipment.

Pipeline and filter device

The pipeline system is responsible for transporting the liquid from the liquid storage tank to the nozzle, keeping the liquid flowing smoothly and the pressure stable. To prevent impurities and particles in the liquid from clogging the nozzle, the system is equipped with a high-efficiency filter device. These filters can effectively intercept impurities, ensure the cleanness of the nozzle aperture, and avoid uneven spraying or equipment damage. At the same time, the filter device design is easy to disassemble and clean, which reduces the difficulty of maintenance and improves the service life and reliability of the equipment.

2. Working principle

The working principle of the adjustable nozzle machine mainly relies on the internal booster system to stably and efficiently transport the liquid from the liquid storage tank to the nozzle. A variety of precision structural designs are used inside the nozzle, such as conical holes, atomizers and guide plates. These designs can effectively adjust the flow rate and spray form of the liquid to ensure the diversity and accuracy of the spraying effect. The conical hole controls the flow rate by changing the cross-sectional area of the liquid flow, thereby affecting the spray distance and pressure; the atomizer subdivides the liquid into extremely fine droplets to form a uniform and delicate mist spray, which helps to improve the spray coverage and absorption efficiency; the guide plate is used to guide the liquid flow, adjust the spray direction and angle, and ensure that the spray range meets the expectations.

Users can flexibly adjust the spray angle of the nozzle through a manual knob or an automatic control system to make the spray cover different spatial ranges. At the same time, the adjustment of the aperture size enables users to accurately control the flow rate of the liquid spray to meet the spray requirements of different concentrations and doses. In addition, the adjustment of the spray pressure not only affects the distance and speed of the spray, but also determines the shape and distribution density of the spray, thereby achieving refined management of the spray concentration and effect. Through these adjustable functions, the adjustable nozzle can adapt to various complex application scenarios, from large-area uniform spraying to local high-intensity spraying, greatly improving the operation efficiency and spraying quality.

3. Main features

Adjustable spray mode

The adjustable nozzle supports multiple spray mode switching, including direct spray, atomization and fan spray. The direct spray mode can produce a concentrated and strong water column, which is suitable for long-distance precision spraying; the atomization mode breaks down the liquid medicine into fine particles to form uniform and delicate droplets, which is suitable for large-area coverage and gas purification; the fan spray can achieve large-scale spraying, which is suitable for large-area uniform spraying. The diversified spray modes greatly enhance the adaptability of the equipment and meet various complex spraying needs.

Flexible control of flow and pressure

The device allows users to flexibly adjust the output volume and spraying pressure of the liquid medicine according to specific application requirements. By adjusting the nozzle aperture size and the booster system, users can control the concentration and coverage of the spraying, achieve precise dosage, and avoid waste of resources. Whether it is low-flow fine mist spraying or high-flow powerful spraying, it can be easily achieved through the adjustment function of the equipment, thereby improving the spraying efficiency.

Strong adaptability

The adjustable nozzle machine can adapt to a variety of use occasions and liquid media. It is not only suitable for clean water, but also can be used to spray liquids such as pesticides, disinfectants, fertilizers, lubricants, etc. This wide adaptability makes it perform well in agriculture, industry, environmental protection and other fields, and can meet the needs of different liquid characteristics and working environments.

Easy to maintain

Most nozzle designs have anti-clogging and anti-corrosion functions to ensure that the equipment maintains good performance during long-term use. The nozzle has a reasonable structure and supports quick disassembly and cleaning, which greatly facilitates daily maintenance and maintenance, reduces downtime, and improves the service life and reliability of the equipment.

High degree of automation

Some high-end models are equipped with intelligent control systems, which support timed spraying, program control and remote monitoring functions. Users can remotely manage spraying tasks through electronic panels or terminals such as mobile phones and computers, realize unattended automated operations, and improve operational convenience and management efficiency.

4. Common application areas

Agricultural spraying

In modern agricultural production, Adjustable nozzle-machino play a key role, especially in the precise spraying of pesticides and fertilizers. The equipment can flexibly adjust the spray particle size and spraying range according to the type of crop and the growth stage to ensure that pesticides and fertilizers are evenly covered on the leaves and roots of crops. Uniform spraying not only improves the utilization rate of pesticides and the absorption efficiency of fertilizers, significantly enhances the effect of preventing and controlling pests and diseases and promoting plant growth, but also reduces resource waste and environmental pollution caused by excessive use. In addition, precise control of the spraying amount can reduce the impact on soil and water sources, promote green agriculture and sustainable development, and meet the dual needs of modern agriculture for environmental protection and efficient production.

Industrial dust reduction

In industrial environments with high dust emissions such as mining, building materials processing, and steel metallurgy, the adjustable nozzle sprays fine water mist to effectively absorb suspended particles in the air, reduce dust concentration, and improve the air quality of workshops and work areas. The fine water mist particles can quickly combine with dust and settle to the ground, reducing the spread of dust, helping to control the harm of dust to workers' health and reduce the risk of occupational diseases. At the same time, this wet dust reduction method meets national and local environmental emission standards, which helps companies pass environmental supervision and acceptance smoothly. Flexible adjustment of spraying intensity and range can also save water and energy according to specific working conditions, and improve dust reduction efficiency.

Environmental disinfection

In public places, medical institutions, industrial plants and other places with large traffic or high environmental hygiene requirements, Adjustable nozzle-machino can be used to spray disinfectants over a large area, quickly cover every corner of the space, and kill harmful microorganisms such as bacteria and viruses. The device supports multiple spraying modes, and can choose atomization or fan-shaped spraying according to disinfection needs to ensure uniform distribution of disinfectants and improve disinfection effects. The automatic control function makes the disinfection process more accurate and efficient, reduces manpower input, and reduces the waste of disinfectants. This will help ensure environmental hygiene and safety, prevent the spread of diseases, and play an important role in public health events.

Cooling and humidification

In industrial plants, greenhouses, farms and other environments where temperature and humidity need to be adjusted, the adjustable nozzle machine uses spray to cool and humidify the air. The fine water mist sprayed evaporates quickly in the air, taking away a lot of heat, thereby reducing the ambient temperature and alleviating the heat stress of equipment and operators. Proper humidity regulation helps improve the growth environment of crops and animals, reduce water evaporation and disease occurrence, and improve yield and quality. The flexible spray control system supports timing and precision spraying, making environmental regulation more intelligent and energy-saving, and improving overall operating efficiency.

Spray treatment

The adjustable nozzle machine can also be used for spraying operations on the surface of mechanical equipment and industrial products, such as evenly spraying lubricants, rust inhibitors, cleaning fluids and other chemical liquids. The equipment ensures that the spray liquid evenly covers the target surface by precisely controlling the spray particle size and flow rate to form a stable and effective protective layer. This not only improves the service life and operational stability of the equipment, but also reduces maintenance frequency and cost. During the spraying process, the spray pattern can be flexibly adjusted to meet different material properties and process requirements, and is widely used in machinery manufacturing, automobile maintenance, electronic equipment protection and other industries.

5. Advantages Summary

Precise control

The adjustable nozzle machine can achieve precise control of the spray effect, ensuring that the sprayed liquid particles are uniform and fine, and the spray coverage is wide and uniform. By adjusting the nozzle angle, flow rate and pressure, the equipment can meet the specific requirements of different operating scenarios for spray form and coverage density, effectively avoiding spray blind spots and overlapping areas, thereby improving the overall quality and consistency of the spray effect.

Flexible operation

The equipment has a variety of spray modes and flow adjustment functions, with strong adaptability, which can meet diverse operating needs. Whether in different scenarios such as agricultural spraying, industrial dust reduction, environmental disinfection, or cooling and humidification, parameters can be easily adjusted to achieve multi-purpose use of one machine, significantly improving the versatility and economy of the equipment. Flexible operation enables users to quickly switch spray modes according to actual needs and improve operating efficiency.

Energy saving and environmental protection

Through precise spray control and flow adjustment, the equipment effectively reduces the use of chemicals and liquid medicines, avoids resource waste and excessive environmental pollution. At the same time, the optimized spraying effect helps to reduce the impact on the environment and promote green production and sustainable development. The equipment design focuses on energy saving and consumption reduction, which further improves the environmental protection performance during use.

Reduce labor

Some models support automatic control and remote monitoring, which can realize timed spraying and intelligent adjustment, greatly reducing the dependence on manual operation. Automated operation not only improves work efficiency, but also reduces human operation errors and ensures the precise execution of spraying tasks. By reducing the manual burden, users can focus more on important links such as production management, thereby improving overall production efficiency.

The adjustable fire hose supports free switching or combination of multiple modes such as direct current, atomization, fan-shaped spraying, water curtain, etc. to adapt to different firefighting scenarios. The following is a detailed introduction to these spraying modes, including their functional characteristics and applicable scenarios:

1. Direct current spraying mode

In direct current spraying mode, the nozzle concentrates and compresses the liquid water flow into a high-speed and stable straight water column. This mode ensures that the water flow is highly concentrated and reduces diffusion through the special structural design inside the nozzle, thereby forming a strong and precise water column spray.

Product features

The direct current spray mode has a strong impact force, can spray water columns at high speed, and has a long and stable range. The concentrated water column can penetrate the surface of the flame and directly act on the core of the combustion, with a significant fire extinguishing penetration effect. The powerful water column can quickly cool and suppress the fire, shorten the fire extinguishing time and improve the fire extinguishing efficiency.

Applicable scenarios

This mode is particularly suitable for fire extinguishing operations in medium and high-rise building fires and long-distance fire sources. Firefighters can use this mode to spray accurately from a farther position, effectively controlling the fire while ensuring a safe distance. In addition, the DC jet water column can penetrate the window glass, impact and destroy the surface structure of the burning object, which helps to quickly extinguish the fire source hidden in the room or behind obstacles, and enhance the flexibility and practicality of fire extinguishing.

2. Atomization spray mode

The atomization spray mode subdivides the water flow into a large number of extremely fine water droplets through the atomization mechanism inside the nozzle, forming a dense and uniform water mist cloud. These fine water droplets have a large surface area and can quickly and fully contact the heat and harmful substances in the air, thereby achieving an efficient cooling and purification effect.

Features

The fine water mist mode has a wide coverage range and can form a continuous and dense water mist layer, which effectively absorbs a large amount of heat and significantly reduces the temperature at the fire scene. Its tiny water droplets can evaporate quickly, have a strong heat absorption effect, and have a significant cooling effect. At the same time, fine water mist can also dilute and reduce the concentration of toxic gases, reduce the harm of harmful smoke, and effectively reduce the intensity of radiant heat, protecting firefighters and the on-site environment. In addition, fine water mist also has good dust reduction and anti-reignition capabilities, further improving the fire extinguishing effect and safety performance.

Applicable scenarios

The atomization spray mode is particularly suitable for electrical fire scenes. The fine water mist can avoid strong water columns directly impacting electrical equipment, reducing the risk of electrical short circuits and equipment damage. This mode is also suitable for confined space fires and toxic smoke environments, which can effectively suppress the spread of smoke, reduce the concentration of harmful gases, and provide a safer working environment for rescue and firefighting.

3. Fan-shaped spray mode

In the fan-shaped spray mode, the nozzle sprays the water flow evenly in a fan shape, forming a wide and uniform spray coverage range. This mode uses a unique spraying structure inside the nozzle to make the water flow fan-shaped, which can quickly cover a large area.

Features

The fan-shaped spraying mode can quickly cover a large area of the ground or the surface of an object, effectively improving the efficiency of fire extinguishing or cooling. Its uniform spraying avoids dead corners and omissions, and is suitable for fire extinguishing, cooling treatment and cleaning operations of ground fire sources. This mode can maintain good water flow coverage intensity and achieve accurate and comprehensive fire extinguishing effects.

Applicable scenarios

This mode is very suitable for extinguishing large-area ground or wall fires, especially in places such as warehouses and factories where fire sources are dispersed and widely distributed. It can quickly control the fire, prevent the spread of the fire, and ensure the safety of the site and property.

4. Water curtain mode

The water curtain mode forms a continuous and dense vertical or inclined water curtain wall through a special nozzle design. The water curtain is like a transparent water wall, which effectively isolates flames and heat radiation and blocks the spread of fire.

Features

The water curtain can strongly block the spread of heat waves, flames and smoke, and protect firefighters and on-site equipment from high temperature damage. It can also form a temporary safe passage or protection area at the fire scene to facilitate the safe evacuation of personnel or rescue operations. Water curtain walls not only play a role in heat insulation and fire prevention, but also purify the air and improve the on-site environment.

Applicable scenarios

This mode is suitable for harsh environments with high temperature and high heat radiation, especially for barrier protection in hazardous chemical storage areas such as petrochemical plants and oil depots. Through the isolation of the water curtain wall, the spread of fire and the risk of explosion can be effectively prevented, and the level of safety protection can be improved.

5. Combination mode

The combination mode allows operators to flexibly switch different spraying modes through manual or automatic control systems according to the on-site fire conditions and operational requirements, or combine multiple spraying methods at the same time to achieve multi-functional dynamic response.

Features

This mode has strong adaptability and flexibility, and can quickly respond to complex and changing fire conditions. By switching and combining between modes, operators can efficiently use equipment resources, save fire extinguishing time, and improve the overall fire extinguishing effect and operational safety. The combination mode is particularly suitable for occasions with complex fire environments and diverse fire sources.

Applicable scenarios

The combined mode is widely used in multi-source fires and changing environments, such as large commercial buildings, ships, tunnels and industrial parks. In the face of complex fires in multiple areas and multiple ignition points, the spraying mode can be flexibly adjusted to effectively improve the pertinence and efficiency of firefighting work.

| Spray mode | Spray shape | Features | Applicable scenarios |

| DC spray mode | Linear spray | The liquid is sprayed in a straight line, with strong impact and small coverage | Applicable to occasions requiring high-intensity impact, such as cleaning and cooling |

| Atomized spray mode | Fine droplets | Fine droplets are produced only through liquid pressure, with good dispersion | Applicable to cooling, humidification, evaporation and other scenarios requiring high dispersion |

| Fan spray mode | Fan-shaped distribution | The spray is fan-shaped, with moderate coverage and relatively uniform impact | Applicable to conveyor belt cleaning, coating, wetting and other scenarios requiring uniform coverage |

| Water curtain mode | Large area coverage | The spray is in the shape of a water curtain, with a wide coverage and weak impact | Applicable to large-area cooling, fire prevention, dust removal and other scenarios requiring wide coverage |

| Combined mode | Combination of multiple modes | Different spray modes can be combined according to needs, with high flexibility | Applicable to complex application scenarios, such as multi-stage cleaning, cooling and humidification |

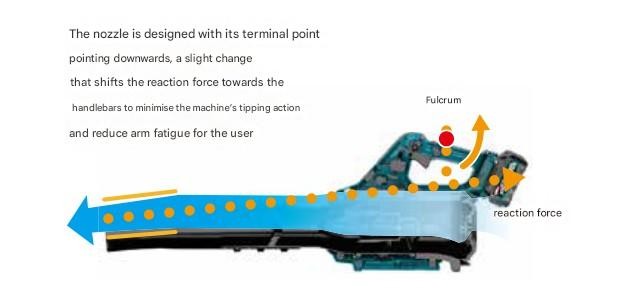

How does the recoilless design of the adjustable nozzle machine reduce the fatigue of the operator?

The recoilless design of the adjustable nozzle machine significantly reduces the fatigue of the operator by optimizing the nozzle structure and operating experience. The core of the recoilless design is to use the reaction force generated by the nozzle to offset the recoil of the artillery or spray gun, thereby reducing the thrust and reverse thrust during operation and making the operation smoother. This design not only reduces the fatigue after long-term use, but also improves the safety of operation.

In practical applications, the design of the recoilless nozzle usually includes the following aspects:

Nozzle structure optimization: By adjusting the outlet diameter and key section diameter of the nozzle, the recoil can be effectively controlled. For example, studies have shown that changing the shape and size of the nozzle can significantly affect the recoilless state, thereby improving stability and accuracy. In addition, a dual nozzle design has also been proposed to reduce bullet velocity loss and improve recoil efficiency.

Reduce operating fatigue: The design of the recoilless nozzle usually adopts ergonomic principles to reduce the muscle burden of the operator. For example, the grip of the spray gun is designed in an ergonomic shape to reduce hand fatigue. At the same time, the adjustment of the terminal point position of the nozzle can also transfer the reaction force to the side of the handle, thereby minimizing the back-tilting action of the machine and reducing arm fatigue.

Improve operating comfort: The design of the recoilless nozzle also takes into account the comfort of operation. For example, the trigger of the spray gun is designed to be light and easy to operate to reduce muscle tension and fatigue. In addition, the spray angle and flow adjustment functions of the nozzle also make the operation more flexible and efficient.

Safety and reliability: The design of the recoilless nozzle also focuses on safety, such as improving the efficiency and safety of use through anti-entanglement design and automatic adjustment of the water hose function. At the same time, the structural design of the nozzle also ensures its stability and durability under high pressure.

Grooved Fire Elbow-Storz

Grooved Fire Elbow-Storz

Grooved Fire Elbow-Multi-tooth

Grooved Fire Elbow-Multi-tooth

Multi-functional Fire Hose Distributor

Multi-functional Fire Hose Distributor

Locking Four-Way Fire Hose Distributor

Locking Four-Way Fire Hose Distributor

Locking Three-Way Fire Hose Distributor

Locking Three-Way Fire Hose Distributor

Locking Two-Way Fire Hose Distributor

Locking Two-Way Fire Hose Distributor

Straight Stream Nozzle

Straight Stream Nozzle

Adjustable nozzle-machino

Adjustable nozzle-machino

Adjustable nozzle-storz

Adjustable nozzle-storz

Storz Adapter Couplings - Multi-Tooth

Storz Adapter Couplings - Multi-Tooth

Machino Adapter Couplings – Flanged

Machino Adapter Couplings – Flanged

Storz Adapter Couplings – Flanged

Storz Adapter Couplings – Flanged